AUTOMATIC CONTINUOUS HEAT TREATMENT LINE WITH CASTBELT FURNACE

Automatic continuous heat treatment line with CASTBELT furnace, for hardening and tempering of metal parts (bolts and nuts), production 600 kg/h, composed by:

- Vibrating hopper capacity 1000 dm3 with electronic weighing

- Rotary drum pre-dephosphatizing and washing machine

- Continuous CASTBELT model 251 (W 800 x L 4100 mm) hardening furnace, with cast belt and gas heating through high efficiency recuperative burners

- Oil quenching tank

- Rotary drum washing machine

- Continuous TURBOMAX CF.AN (W 800 x L 6.000 mm) conveyor belt tempering furnace, with gas heating through high efficiency recuperative burners

- Final water quenching tank

- Endothermic generator model ENDOSIB 442 to produce the controlled atmosphere for the hardening furnace

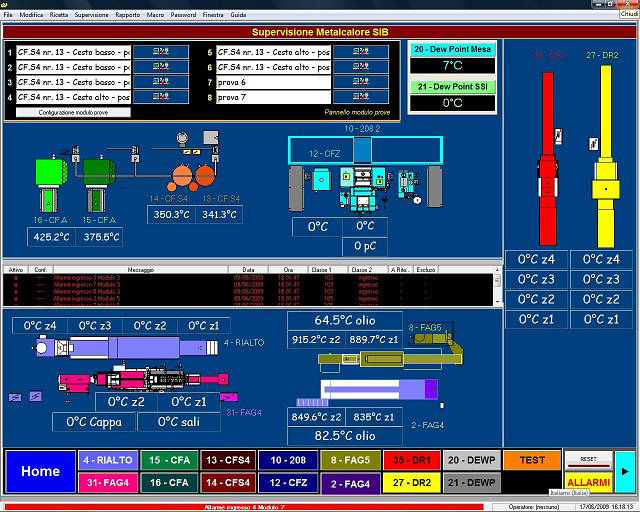

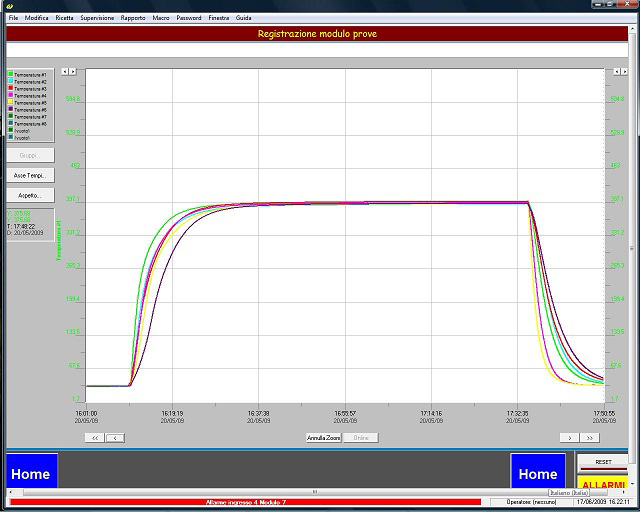

- Electric cabinet with Siemens PLC and Supervision System SIBVISION

SPECIAL FURNACE FOR SINTERING OF DIAMOND TOOLS

PROTEMAX 1641 in special execution for diamond tools sintering, composed by:

- Horizontal cylindrical retort

- Two heating zones to grant a great temperature uniformity inside the chamber

- System to catch and clean the wax

- Cooling fast system to reduce the total cycle time

- Hydrogen controlled atmosphere

- Electric cabinet with cycle programmer, temperature recorder, PLC, operator panel

SPECIAL FURNACE FOR CHROMIZING OF SMALL METAL PARTS

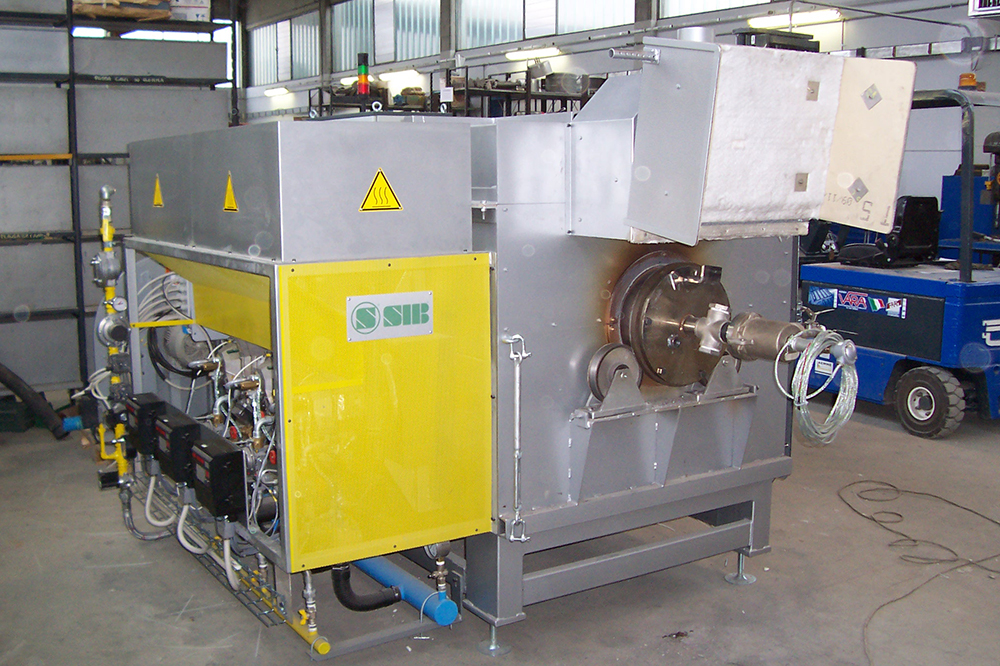

Rotative retort furnace for chromizing of small metal parts composed by:

- Rotative retort horizontal furnace

- Gas heating with recuperative burners

- Cycle programmer

- Two independent heating zones

- External loader on rails

- Electric cabinet with PLC and operator panel

STATION FOR BRAKE DISKS TEMPERING UNDER PRESSURE

Bell type station for tempering of brake disks under pressure, composed by:

- Bell type furnace

- Three loading / treating platforms

- Press system of the charge during treatment

- Automation and motorized translations

- Electric cabinet with PLC and operator panel

PIT FURNACE WITH VACUUM CYCLE

Pit furnace model 575 with the following characteristics:

- Charge dimensions: Ø 600 x H 1400 mm

- Max temperature: 1100°C

- Heat treatment: inox steel solubilization

- Pump for vacuum cycle

- Heat treatment under nitrogen / argon protective gas

- Electric cabinet with PLC and video-screen temperature recorder